Mark Orazem, Ph.D., a Distinguished Professor and the Dr. and Mrs. Frederick C. Edie Professor at the University of Florida Department of Chemical Engineering, was awarded a three-year research contract from the Nuclear Waste Management Organization (NWMO) of Canada to develop a damage model of copper corrosion within nuclear fuel waste containers placed in deep geological repositories. The NWMO is responsible for the safe, long-term management of Canada’s used nuclear fuel.

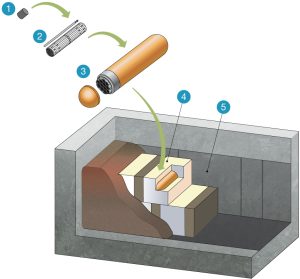

A multiple-barrier system is designed to safely contain, and isolate used nuclear fuel and protect people and the environment. The present design of Canadian nuclear fuel waste containers consists of a thick-walled steel vessel coated with a thin copper layer intended to provide corrosion protection. Each of the five barriers provides a unique and stand-alone level of protection. If any of the barriers deteriorate, the next one comes into play.

Dr. Orazem and Chen You, a Ph.D. student in the Orazem lab, are developing a model to understand how the copper-coated container will withstand humidity inside the repository environment. This modelling will help the NWMO better understand the long lifecycle of the repository.

“Deep geological repositories are the international standard for the safe, long-term storage of used nuclear fuel, and the NWMO is helping to lead the way,” said Dr. Orazem. “Our work will help the NWMO assess the potential for corrosion of their copper-coated safety container.”

Dr. Orazem is a renowned expert in corrosion modelling and has previously worked on other international deep geological repository projects, including the SKB project in Sweden, among many other industrial and public projects.

“The NWMO’s research has already demonstrated the multiple barrier system is a safe, long-term solution for used nuclear fuel. The work being done at the University of Florida by Dr. Orazem’s team will further underscore our safety assessment work and add more confidence in the copper-coated container’s ability to withstand any contact with moisture, even centuries in the future,” said Dr. Scott Briggs, an Associate Engineer with the NWMO. “The modelling being worked on will increase our confidence in the corrosion allowance — the amount of copper that can be damaged over time — while still ensuring the long-term integrity of the container.”