The bad news: The Chemical Engineering building is closed for a years-long renovation. The good news: The department’s Unit Ops Laboratory has been relocated to the Nuclear Science building, and there are 13 new pieces of equipment in the teaching lab.

This new equipment is thanks to a $500,000 contribution from the Herbert Wertheim College of Engineering. The lab’s vision was conceived by former department chair Carlos Rinaldi-Ramos, Ph.D.

ChemE students take courses in the lab during their junior and senior years.

The student chapter of the American Institute of Chemical Engineers, known as AIChE, has two design teams that work on their projects in the lab. The ChemE Car team won the regional competition in the spring and qualified for nationals. The ChemE Cube team also qualified for their national competition via a virtual design presentation, said LiLu Funkenbusch, Ph.D., the Unit Operations Lab director and an instructional assistant professor.

The lab features a new, state-of-the-art fast protein liquid chromatograph (FPLC) unit and a tangential flow filtration unit (TFF). Both units are used in bioprocessing separation (separating waste proteins out of vaccines, for example), according to Funkenbusch.

“Bioprocessing/pharmaceuticals is a growing field for our students, and these are some of the most used unit operations in those areas. We purchased Cytiva units, which are gold standards in the industry. They even include the same control software that the larger units in actual drug/vaccine facilities use,” Funkenbusch said.

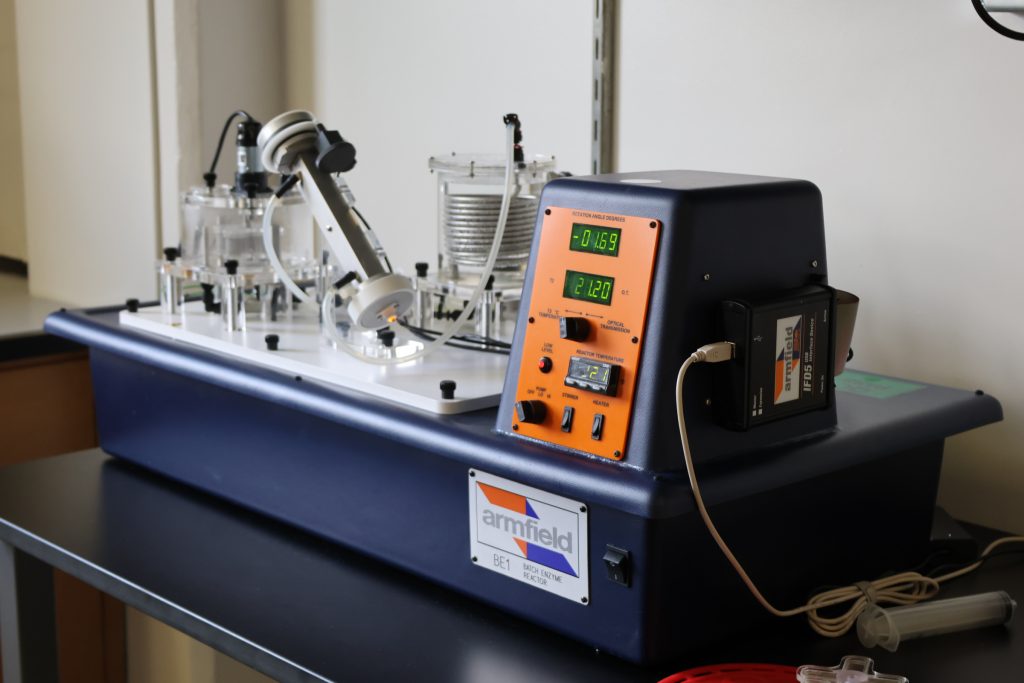

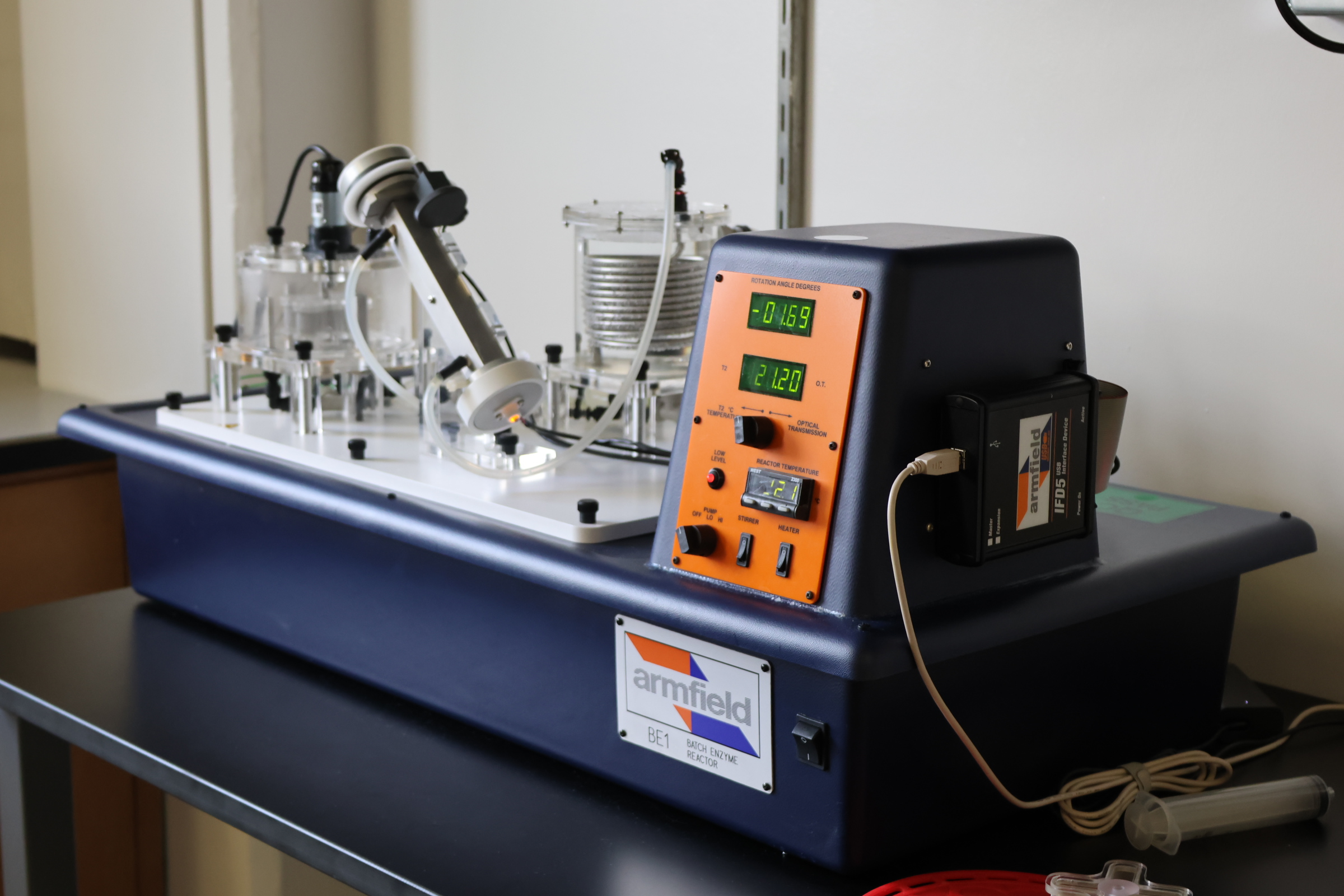

Some of the other units are more common in teaching labs, as the department wants to focus on the units students likely will see in their careers, such as pumps, heat exchangers and reactors. All of the new units are computer-controlled.

“This provides our students with a more realistic experience since very few industrial-scale processes require engineers to physically go out into the facility to manipulate controls,” Funkenbusch said.

The two-story distillation columns were replaced with a new unit that’s about 10 feet tall. The old filtration unit and packed bed system were repurposed into tangential flow filtration and chromatography units to reflect the types of equipment graduates will encounter.

Students learn about chemical and process safety, outlining specific hazards through training on the first day of class and analyzing every experiment prior to running it.

Maintaining the equipment falls to ChemE Staff Engineer Preston Towns.

“It’s not hard to maintain any individual unit, but we’ve got about 15 pieces of equipment. The new ones have quirks we need to figure out and sometimes fix, and the old ones are aging and frequently need a tune-up. It’s a lot of work, and we’re very lucky to have Preston helping us out,” said Funkenbusch.

Even though some of the equipment is new, there were many things to optimize. One item on the wish list was a manifold for the modular heat exchanger, which allows students to open and close valves to use an individual heat-exchanger module rather than requiring them to remove and attach hoses and tubes to the control unit each time.

Towns built that set up, and he is working to streamline modular reactors in a similar fashion.

The old Unit Ops Lab was about 10,000 square feet. But for now, it is squeezed into about 2,500 square feet. Once the department moves back into the remodeled building, the teaching labs will expand back up to about 6,000 square feet. Most of the additional 3,500 square feet will be dedicated to adding new experiences and experiments.

The new lab will also house a bioprocessing lab and a semiconductor fabrication space with a lithography machine to introduce students to this rapidly growing industry.

For an interactive, 3-D view of the current lab, visit here.