In science, catalysts speed up chemical reactions without themselves undergoing permanent changes in the process. Few people think about catalysts in everyday life, but they are the backbone of chemical engineering in industrial applications.

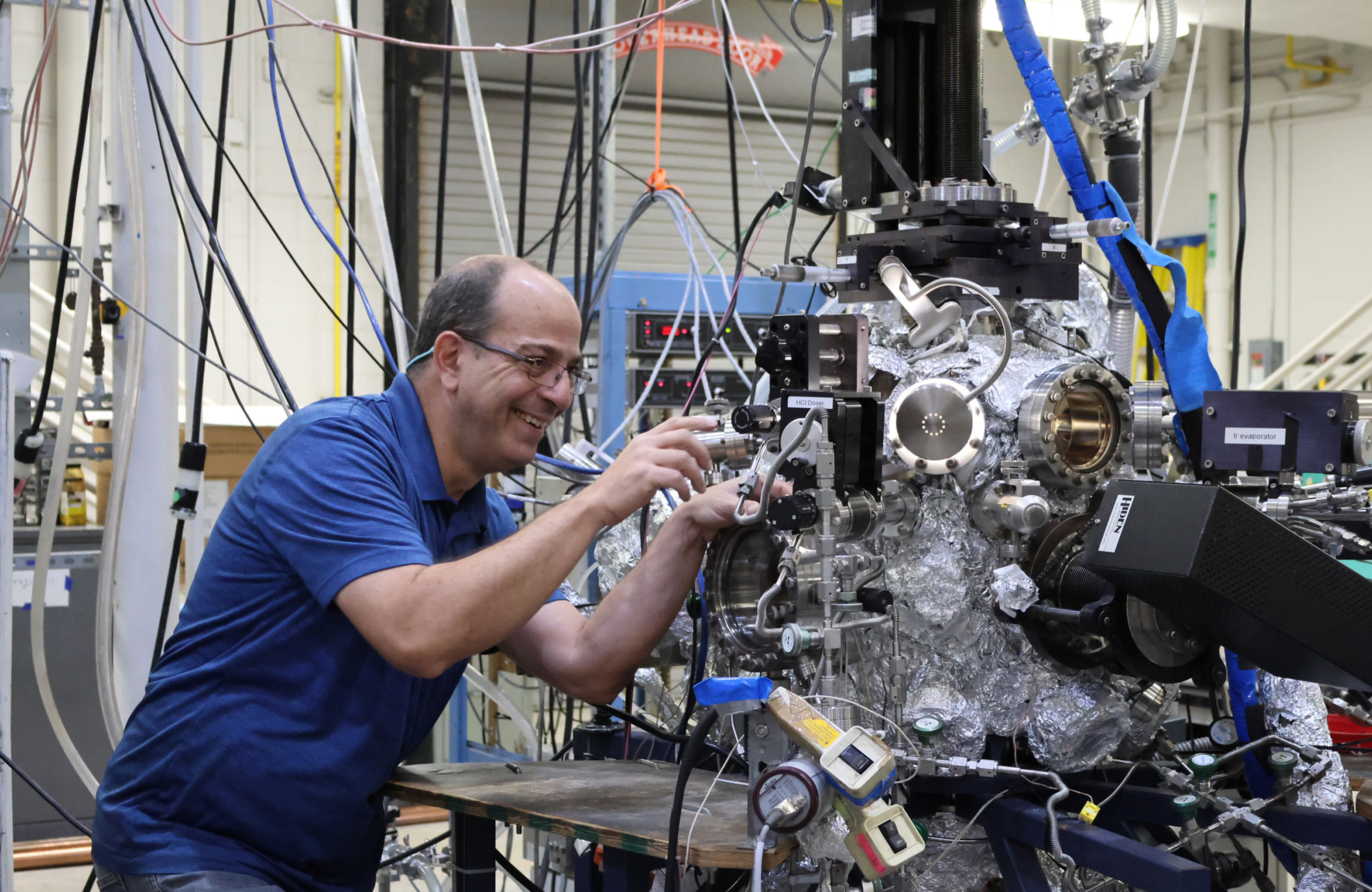

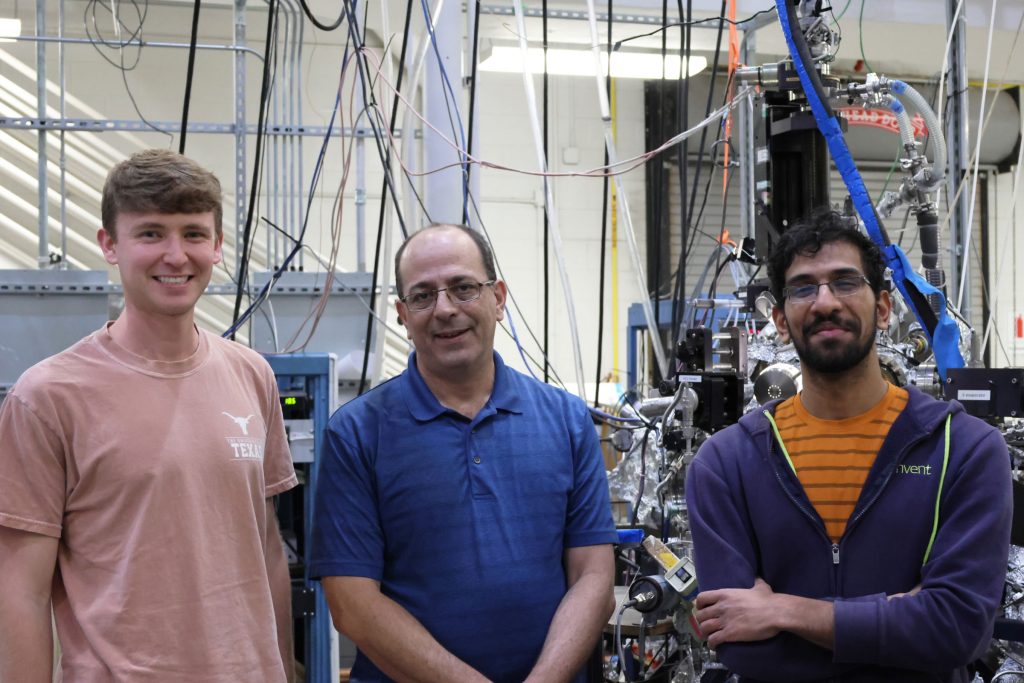

University of Florida Professor Jason Weaver, Ph.D., knows the process well and recently co-authored a research paper with colleagues about the creation of a new, stable catalyst.

“These types of designer catalysts are of great interest in developing and improving catalytic processes for applications including synthesis, energy conversion and pollution control,” said Weaver, UF’s Dow Chemical Company Foundation Term Professor.

An everyday example of a catalyst is the yeast we use in baking bread. It contains natural catalysts that help convert the flour into risen bread.

In industrial settings, catalysts are used to speed up processes, thus saving energy and money, and reducing harmful emissions while producing fertilizers, anti-freeze or renewable fuels, for example.

Industries use catalysts to break down the cellulose in biomass — such as corn or trees — to make fuel. They help convert petroleum into plastic products. They are used to harden vegetable oils to create margarine. They help the synthesis of ammonia to make fertilizers.

Technically, a catalyst is a combination of substances that lowers the temperature or pressure needed to start a chemical reaction, without itself being consumed during the reaction.

During the chemical reaction, the bonds between the atoms in molecules are broken, rearranged and rebuilt, recombining the atoms into new molecules. Catalysts make this process more efficient by lowering the activation of energy, which is the energy barrier that must be surmounted for a chemical reaction to occur.

As a result, catalysts make it easier for atoms to break and form chemical bonds to produce new combinations and new substances.

The team’s paper described how they combined two metals into atomic pairs — platinum and chromium in a bed of silver — to create a new kind of catalyst that could be used for ethanol dehydrogenation. That’s the chemical reaction that removes hydrogen from ethanol to produce acetaldehyde and hydrogen gas for energy.

They achieved their research goal, ensuring that the platinum and chromium pairs stayed dispersed in the silver background, so the material stayed stable and the catalysts didn’t degrade, which would require more replacements. This is important to ensure long-term efficiency and reduced costs in chemical processes.

Their research took place in laboratories in several countries, including the United States and Sweden. The results were published in Angewandte Chemie, a prestigious, peer-reviewed, scientific German publication.

Fun Fact: The German term Angewandte Chemie translates to “Applied Chemistry” and covers all aspects of chemistry – not just applied chemistry. The journal boasts a 20% overall acceptance rate and a 7% acceptance rate for U.S. submitters.